VALUE VRD Industrial Rotary Vacuum Pump

Rotary Vane Pump Animation

Download Files

Value_VRD-30_Product_Catalogue_(27-7-2023).pdf (45.64 KB)

Value_VRD-30_Product_Catalogue_(27-7-2023).pdf (45.64 KB)

ROTARY_(VANE)_VACUUM_PUMP_OPERATION.pdf (155.32 KB)

ROTARY_(VANE)_VACUUM_PUMP_OPERATION.pdf (155.32 KB)

VRD_Value_Industrial_Vacuum_Pump_Manual_(Part_2)_15-8-15.pdf (6.89 MB)

VRD_Value_Industrial_Vacuum_Pump_Manual_(Part_2)_15-8-15.pdf (6.89 MB)

VRD_Value_Industrial_Vacuum_Pump_Manual_(Part_1)_15-8-15.pdf (5 MB)

VRD_Value_Industrial_Vacuum_Pump_Manual_(Part_1)_15-8-15.pdf (5 MB)

Value_Industrial_Vacuum_Pump_VRD_Model_(27-2-15).jpg (133.02 KB)

Value_Industrial_Vacuum_Pump_VRD_Model_(27-2-15).jpg (133.02 KB)

Value_VRD-30_Rotary_Vacuum_Pump_Installation.pdf (792.36 KB)

Value_VRD-30_Rotary_Vacuum_Pump_Installation.pdf (792.36 KB)

2012_VRD_Catalogue.pdf (5.51 MB)

2012_VRD_Catalogue.pdf (5.51 MB)

Value_VRD_Industrial_Rotary_Vacuum_Pump.pdf (70.43 KB)

Value_VRD_Industrial_Rotary_Vacuum_Pump.pdf (70.43 KB)

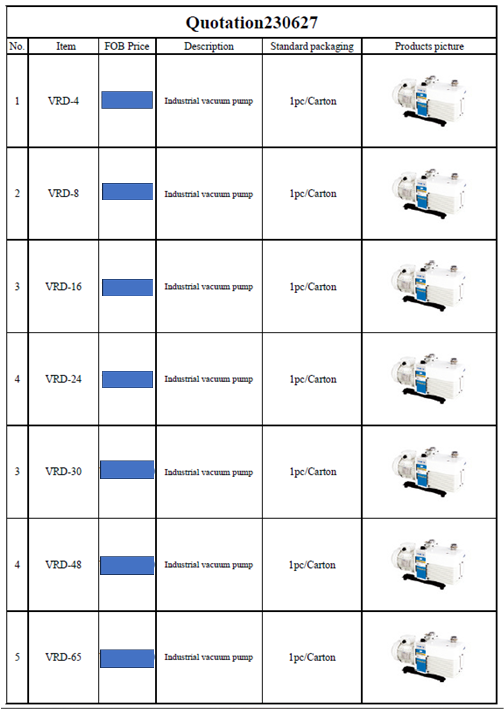

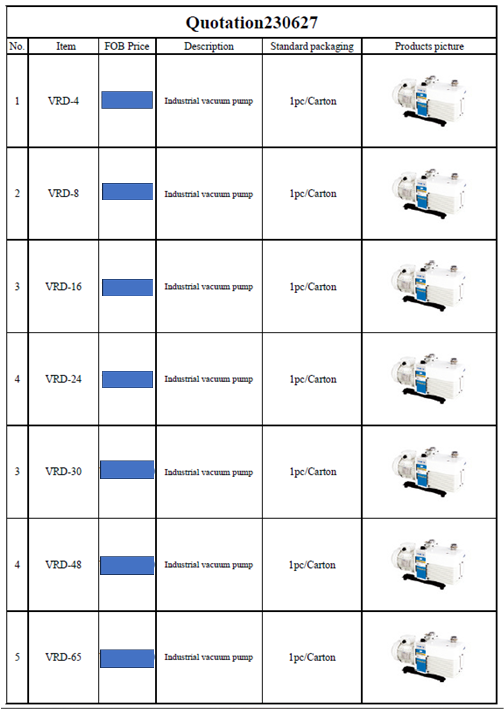

VALUE VRD Industrial Rotary Vacuum Pump

Model Available

Optional Item

NW-40 (Tube Dia. 1-1/2'' Or 38mm) Long Flange

NW-25 (Tube Dia. 1'') Long Flange

https://www.htcvacuum.com/en-global/product/index/vacuum-components/vacuum-flanges/kf-nw-flanges/half-nipple-long

Accessories

Excellent Performance

The purpose of a vacuum pump is to remove moisture and air from an A/C-R system. Modern systems are built tighter and charges are more critical. That means these systems have a greater sensitivity to moisture and other contaminants, making thorough evacuation more important than ever before.

Moisture in a refrigeration system, directly or indirectly, is the cause of most problems and complaints. First, moisture can cause freeze-up in a system. Moisture is picked up by the refrigerant and transported through the refrigerant line in a fine mist, with ice crystals forming at the point of expansion.

“Freeze-up” is not the only problem caused by moisture. It can also result in corrosion, the effects of which are not apparent until the real damage has occurred.

Moisture alone is bad enough, but combined with refrigerants containing chlorine, hydrochloric acids can form. These greatly increase the corrosion of metals.

Also, refrigerant oil rapidly absorbs moisture. Water-formed acids combine with the refrigerant, forming a closely bonded mixture of fine globules.

The effect is called sludging and it greatly reduces the lubricating ability of the oil.

A vacuum pump removes troublesome moisture by lowering the pressure within the system and vaporizing (or boiling off) the moisture, then exhausting it along with air.

Operation

It can continue work 10-14hours without stop. But please make sure sufficient oil.

Model Available

- VALUE VRD-16 (1PH [0.75KW Or 1HP]/3PH [0.55KW Or 0.74HP]) (9.32 CFM) Rotary Vacuum Pump

- VALUE VRD-24 (1PH [0.75KW Or 1HP/3PH [1.1KW Or 1.48HP) (14 CFM) Rotary Vacuum Pump

- VALUE VRD-30 (1PH/3PH [1.1KW Or 1.48HP]) (17.655 CFM) Rotary Vacuum Pump = RM8,500.00 per unit (1-6-2022=30.51)

- VALUE VRD-48 (3PH [1.5KW Or 2.0HP) (28.3 CFM) Rotary Vacuum Pump

- VALUE VRD-65 (3PH [2.2KW Or 2.95HP) (38.14 CFM) Rotary Vacuum Pump

Optional Item

NW-40 (Tube Dia. 1-1/2'' Or 38mm) Long Flange

NW-25 (Tube Dia. 1'') Long Flange

https://www.htcvacuum.com/en-global/product/index/vacuum-components/vacuum-flanges/kf-nw-flanges/half-nipple-long

Accessories

DN-25 KF ALUMINUM CLAMPING RING FOR VACUUM PUMP

DN-25 KF CENTERING RING WITH VITON ORING FOR VACUUM PUMP

Spare Parts

Spare Parts

VALUE RUBBER MOUNTING COUPLING FOR VRD-65 3PH ROTARY VACUUM PUMP

VALUE VRD-30 VACUUM PUMP BODY (SPARE PART)

VALUE VRD-30 VACUUM PUMP FAN MOTOR

- Integrated cylinder structure and high precision design to ensure the pump is able to work reliably in various conditions

- Constant oil supply pressure system is utilised to maintain the lubrication quality of the oil as well as the reliability of the internal seals. Both measures have been taken to further enhance the reliability and the durability of the vacuum pump.

- Automatic anti-backflow valve design, to protect the vacuum pump system from the contamination of the oil and the oil vapour after the pump has been stopped.

- Double gas ballast, meet the different requirements of steam exhaustion.

- Imported oil and fluororubber seals to suit different working conditions

The purpose of a vacuum pump is to remove moisture and air from an A/C-R system. Modern systems are built tighter and charges are more critical. That means these systems have a greater sensitivity to moisture and other contaminants, making thorough evacuation more important than ever before.

Moisture in a refrigeration system, directly or indirectly, is the cause of most problems and complaints. First, moisture can cause freeze-up in a system. Moisture is picked up by the refrigerant and transported through the refrigerant line in a fine mist, with ice crystals forming at the point of expansion.

“Freeze-up” is not the only problem caused by moisture. It can also result in corrosion, the effects of which are not apparent until the real damage has occurred.

Moisture alone is bad enough, but combined with refrigerants containing chlorine, hydrochloric acids can form. These greatly increase the corrosion of metals.

Also, refrigerant oil rapidly absorbs moisture. Water-formed acids combine with the refrigerant, forming a closely bonded mixture of fine globules.

The effect is called sludging and it greatly reduces the lubricating ability of the oil.

A vacuum pump removes troublesome moisture by lowering the pressure within the system and vaporizing (or boiling off) the moisture, then exhausting it along with air.

Operation

It can continue work 10-14hours without stop. But please make sure sufficient oil.